Fundamentals of High Temperature Insulation

High-temperature insulation materials are designed to reduce heat transfer and protect structures from extreme temperatures. These materials are essential in a wide range of industries such as energy, manufacturing, and construction, where processes or machinery generate intense heat. The selection of high-temperature insulation often depends on factors like temperature resistance, thermal conductivity, mechanical strength, and resistance to chemical and environmental factors.

In industrial settings, managing high temperatures effectively is critical for both safety and operational efficiency. High-temperature insulation prevents heat loss, reduces energy consumption, and protects workers from potential hazards. Moreover, it ensures the longevity of equipment by preventing thermal damage. From furnaces and kilns to piping systems, these materials are crucial in maintaining the stability and safety of systems exposed to extreme heat.

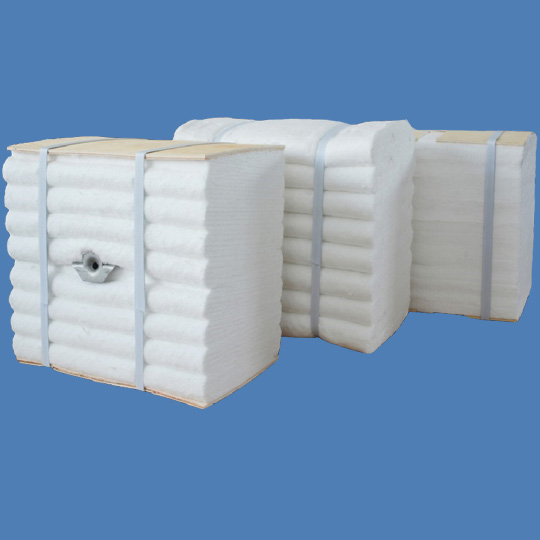

Ceramic Fiber Module

Properties

Ceramic fiber modules are among the most widely used high-temperature insulation materials. Made from spun ceramic fibers, these modules are designed to withstand very high temperatures. They are lightweight, flexible, and highly resistant to thermal shock, which makes them ideal for high-performance insulation needs. Below is a detailed table outlining key properties of ceramic fiber modules:

| Property |

Detail |

| Temperature Resistance |

Up to 2300°F (1260°C) |

| Thermal Conductivity |

0.12-0.14 W/m·K |

| Density |

160-200 kg/m³ |

| Mechanical Strength |

High compression resistance |

| Chemical Resistance |

Resistant to acids and alkalis |

| Flexibility |

Highly flexible for easy installation |

| Fire Resistance |

Non-combustible |

Applications

Ceramic fiber modules have a broad range of applications in various industries. These include:

- Furnace linings

- Kiln insulation

- Fire protection systems

- Heat exchangers

- Steam pipelines

- Boilers and industrial ovens

- Thermal protection for exhaust systems

- Insulation for electrical cables

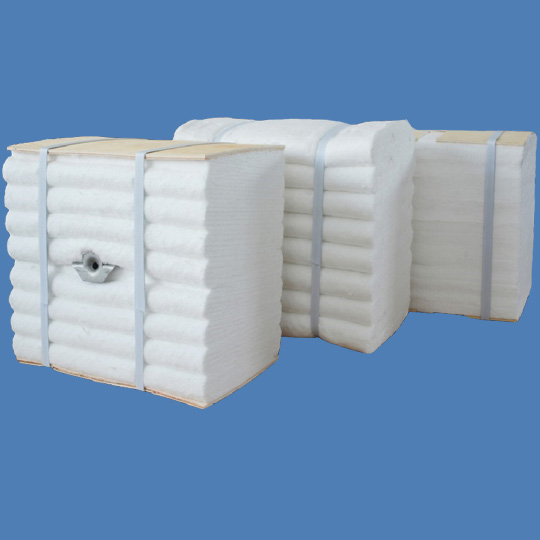

Calcium Silicate Insulation Solutions

Properties

Calcium silicate insulation offers exceptional thermal resistance and high mechanical strength, making it a reliable choice for applications where heat insulation is essential. These materials are known for their low thermal conductivity and resistance to high-temperature degradation. Below is a detailed table of calcium silicate insulation properties:

| Property |

Detail |

| Temperature Resistance |

Up to 1700°F (927°C) |

| Thermal Conductivity |

0.18-0.22 W/m·K |

| Density |

240-290 kg/m³ |

| Compressive Strength |

High compressive strength |

| Fire Resistance |

Non-combustible |

| Chemical Resistance |

Good resistance to acids and bases |

| Durability |

Excellent resistance to weathering |

Applications

Calcium silicate insulation is ideal for high-temperature applications that require durability and high strength. Its primary uses include:

- Insulation for power plants

- Pipe insulation

- Furnace linings

- Thermal insulation in chemical plants

- Insulation for heat exchangers

- Steam distribution systems

- Protective barriers for high-temperature equipment

.jpg)

Thermal Insulation Blanket Technology

Properties

Thermal insulation blankets are designed for versatility in high-temperature environments. They are often made from fiberglass, mineral wool, or other heat-resistant fibers. These blankets offer excellent thermal resistance and are often used for custom-shaped applications. Below is a detailed table highlighting thermal insulation blanket properties:

| Property |

Detail |

| Temperature Resistance |

Up to 2000°F (1093°C) |

| Thermal Conductivity |

0.035-0.045 W/m·K |

| Density |

60-200 kg/m³ |

| Flexibility |

Highly flexible for complex shapes |

| Fire Resistance |

Non-combustible |

| Chemical Resistance |

Resistant to a wide range of chemicals |

| Durability |

Long-lasting in harsh conditions |

Applications

Thermal insulation blankets are commonly used in industries where customization of insulation material is required. Their applications include:

- Insulating pipes and tanks

- Furnace and boiler insulation

- Gasket and sealing applications

- Heat shielding for exhaust systems

- Insulation for industrial ovens and kilns

- Custom insulation for machinery

Thermal Insulation Foam Solutions

Properties

Thermal insulation foam materials are typically used for their lightweight, easy-to-install characteristics. Foam solutions, like rigid foam and spray foam, offer low thermal conductivity and high insulation values. Here’s a detailed table of properties for thermal insulation foam materials:

| Property |

Detail |

| Temperature Resistance |

Up to 1000°F (537°C) |

| Thermal Conductivity |

0.022-0.030 W/m·K |

| Density |

35-150 kg/m³ |

| Compression Strength |

Moderate compression resistance |

| Flexibility |

Low flexibility, rigid |

| Fire Resistance |

Fire retardant |

| Durability |

Excellent resistance to moisture |

Applications

Thermal insulation foam materials are commonly used in the construction, automotive, and energy sectors. Some typical applications include:

- Insulating walls and ceilings in buildings

- Insulation for HVAC ducts

- Insulation for refrigeration systems

- Pipe insulation in industrial plants

- Insulation for cold storage units

- Insulation for automotive parts and components

- Energy-efficient construction applications

Microporous Insulation Innovations

Properties

Microporous insulation materials are advanced solutions that offer extremely low thermal conductivity. These materials consist of a microporous structure, which significantly enhances their insulating properties while maintaining a low weight. Here’s a detailed table of microporous insulation properties:

| Property |

Detail |

| Temperature Resistance |

Up to 3000°F (1649°C) |

| Thermal Conductivity |

0.002-0.004 W/m·K |

| Density |

250-350 kg/m³ |

| Flexibility |

Low flexibility, rigid |

| Fire Resistance |

Non-combustible |

| Durability |

Excellent resistance to thermal cycling |

| Chemical Resistance |

Resistant to a wide range of chemicals |

Applications

Microporous insulation materials are used in applications where extreme temperatures and superior insulation are required. These include:

- High-temperature industrial equipment

- Aerospace applications

- Insulation for cryogenic systems

- Furnace linings and kilns

- Protection for high-temperature piping

- Insulation for catalytic converters

- Thermal protection for space applications

How to Choose

When choosing a material, consider:

- Match the material’s temperature resistance with the operating temperatures of your system.

- Materials with lower thermal conductivity offer better insulating properties.

- Consider materials that can withstand the mechanical stresses of the application.

- Choose materials with high durability if the application requires long-term performance.

- Some materials, like blankets and foams, are easier to install in custom shapes and confined spaces.

By carefully considering these factors, industries can select the optimal high-temperature insulation material for their specific needs.

.jpg)