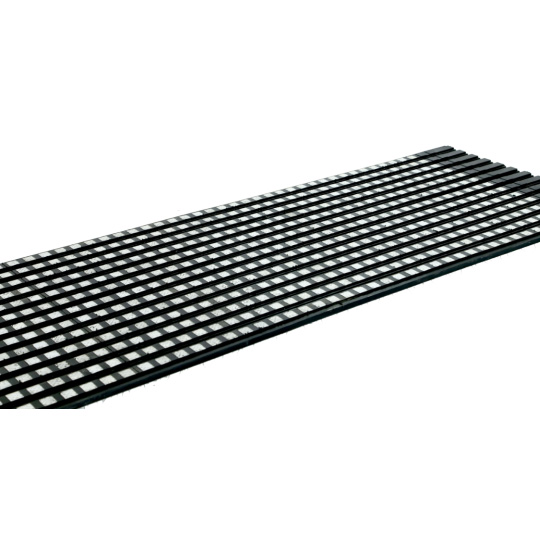

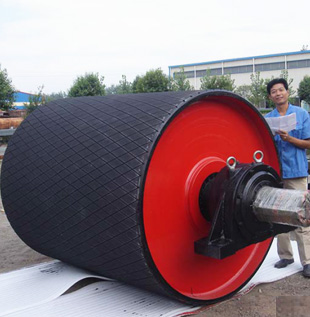

PRODUCT

MINMETALS EAST NEW MATERIAL